Avalanche control is a critical aspect of ensuring safety and maintaining operations in avalanche-prone areas. For industries such as mining, construction, oil and gas, forestry, and infrastructure development, understanding the role of avalanche control is essential for reducing hazards, keeping worksites running, and minimizing downtime.

How Avalanche Control Reduces Operational Hazards

What Is Avalanche Control?

Avalanche control refers to the intentional act of triggering an avalanche. The aim is to reduce or eliminate the avalanche hazard. This can be achieved through a variety of methods, such as the application of explosives, ski cutting, or other mechanical interventions. These measures are typically outlined in an Avalanche Safety Plan (ASP), which is developed after identifying and assessing risks to workers, infrastructure, and other critical elements. Avalanche control is an effective way to minimize the hazard and enhance operational activities.

The Benefits of Avalanche Control for Projects and Operations

Mitigate Avalanche Hazards and Keep Operations Open

Avalanche risk is the probability of harm resulting from the interaction between the avalanche hazard and a specific element (e.g., worker, equipment, infrastructure). By intentionally triggering avalanches in a controlled manner, we effectively mitigate the avalanche hazard component. Once unstable snow is cleared, risk to the operation is often reduced. This allows for continued operational activities such as construction, mining, and logging while enhancing workers’ safety.

Timed Avalanche Control Results in Cost Reduction

Natural avalanches that occur unexpectedly, can lead to expensive emergency responses, overtime pay, accidents and the need for additional personnel. Scheduled avalanche control using various methods allows companies to plan proactively. Controlled avalanche triggering helps reduce costs by allowing operators to plan the timing of snow removal, road closures, and other necessary operations associated with avalanche control. By triggering avalanches in a controlled manner, cleanup can begin immediately, reducing operational downtime and minimizing costly disruptions. This proactive approach results in better management of labor costs and resources, leading to overall cost savings.

Reduces The Potential for Large and Destructive Avalanche Events

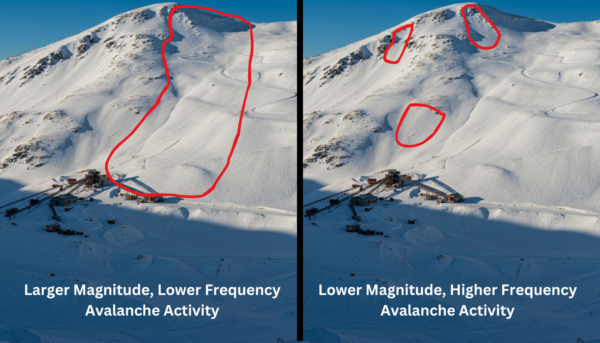

Frequent avalanche control results in the artificial modification of the snowpack. As avalanches are triggered throughout the season, weak layers are triggered and disrupted through the mechanical action of avalanches. This reduces deep instabilities within the snowpack and mitigates the potential for larger avalanches to occur.

Continued avalanche control throughout the winter can reduce the overall volume of snow in avalanche paths. Through the continued triggering of avalanches, snow volumes in start zones are altered which can help reduce avalanche size and/or shorten the length of the avalanche season where avalanche control is implemented.

When is Avalanche Control Most Effective?

Avalanche control measures are often implemented during periods of peak snow instability or after significant weather events. Ongoing monitoring of the snowpack and weather conditions provides valuable insights into the optimal timing for initiating avalanche control. This is typically done by Avalanche Professionals members of the Canadian Avalanche Association (CAA). These workers are deemed competent by the CAA through a rigorous membership process. An avalanche professional will understand all the necessary work required, risks, and measures needed to handle any residual uncertainty.

Steps for Successful Avalanche Control

Develop an Avalanche Safety Plan

An Avalanche Safety Plan is the foundation of any avalanche risk management program. It establishes roles and responsibilities, operational risk band, defines the snow climates, and provides avalanche path mapping. Read about the details of an Avalanche Safety Plan.

Ensure Operational Procedures are in Place

Procedures specific to the operation must be developed for efficient avalanche control. These should be developed in collaboration between the Avalanche Professional and the operations management. A clear understanding of the operational context on all parts will yield safe and effective procedures.

The procedures include but are not limited to:

- Blasting Procedure

- Explosives Transport Procedure

- Workplace & Surrounding Areas Closure Procedures

- Communication Plan

- Snow Removal Procedure

An example of an Avalanche Terrain Atlas Outlining Explosives Placements

Continuous Hazard Assessments

Ongoing evaluation of snowpack conditions, weather patterns, and terrain is vital to adapt control measures as conditions change. Regular assessments ensure that workers remain safe and risks are minimized.

By following these steps, industries can implement proactive and effective avalanche control measures, reducing hazards and maintaining operational stability.

Who Can Perform Avalanche Control?

Avalanche Control is an inherently hazardous activity. Transporting and priming explosives, travelling through avalanche terrain, and managing aviation risks are activities that require advanced skills and training.

At the company level, the organization should maintain certification and approved procedures through Government organizations such as Transport Canada, WorksSafeBC, and (insert relevant US regulator). Procedures must be reviewed and approved yearly by management, and training must be conducted with employees.

Employees should be trained and certified for the work they are doing. This includes maintaining valid Professional membership in organizations such as the Canadian Avalanche Association and the American Avalanche Association. Blasters of Record must ensure they meet minimum training and CPD requirements for their respective blasting licences and adhere to all regulations.

Key Avalanche Control Techniques

Avalanche control involves various methods, each tailored to specific environmental conditions and operational requirements. Typically a combination of the following methods will be used to achieve operational goal.

Various Explosives Deployment

Explosives are one of the most reliable tools for triggering avalanches in a controlled manner. Techniques include:

Hand charging: Placing explosives manually in starting zones to trigger controlled avalanches. These would typically be smaller explosives that can target many start zones. Avalanche Technicians can also deploy larger explosives up to 25kg+ for specific slopes of concern that can be reached with short access or vehicle access. This is advantages when the avalanche zones can be accessed safely by foot; snow can be tested during peak instability when larger avalanches can typically be triggered.

Helicopter deployment: Dropping explosives in remote or inaccessible starting zones, ensuring coverage across large areas. A benefit is bringing large payloads and being able to control a wide variety of terrain. However helicopters are heavily reliant on weather for flying conditions; which does not always line up with peak instability in the snowpack.

Artillery or avaluancher. These are advantageous due to a typically low cost per shot and their ability to maneuver in order to target numerous avalanche start zones. However advanced training is typically required. Some of these launchers such as the howitzer are being phased out.

Use of Remote Avalanche Control Systems (RACS)

RACS (Remote Avalanche Control Systems) deploy an explosive or gas powered blast to a fixed location within the avalanche terrain. Their main benefit is being able proceed with avalanche control at any given point without the need to access the terrain by helicopter or by foot. Due to the wide variety of systems, successful implementations of RACS and choosing the right system tend to require seasoned avalanche engineers and studies to maximize their operational efficiency.

A Summary of Implementing Avalanche Control at Projects and Operations

An Avalanche Safety Plan (ASP) with effective avalanche control enhances accessibility by reducing operational closures and mitigate accidents. By applying a mix of the various methods to an operation like explosive control and advanced solutions like RACS, industries can manage risks while maintaining productivity. For health and safety managers, investing in avalanche control is a vital step in protecting personnel, infrastructure, and economic performance.

Reader Interactions