Abstract

In the avalanche risk management arena, Rogers Pass in Glacier National Park represents the epicenter of avalanche mitigation. A few tragic historical events involving what began as an early 20th century railway corridor inspired scientists and mountain specialists to understand avalanche phenomena and protect those that work and travel in and around it.

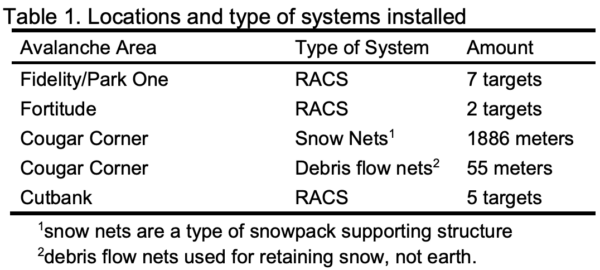

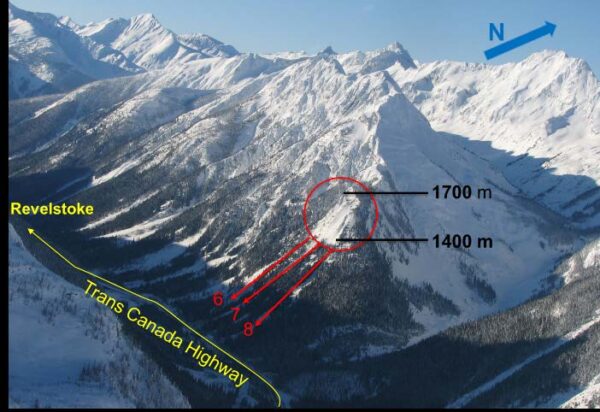

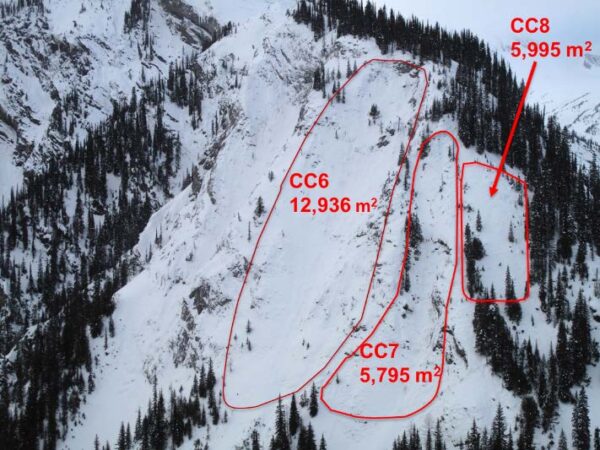

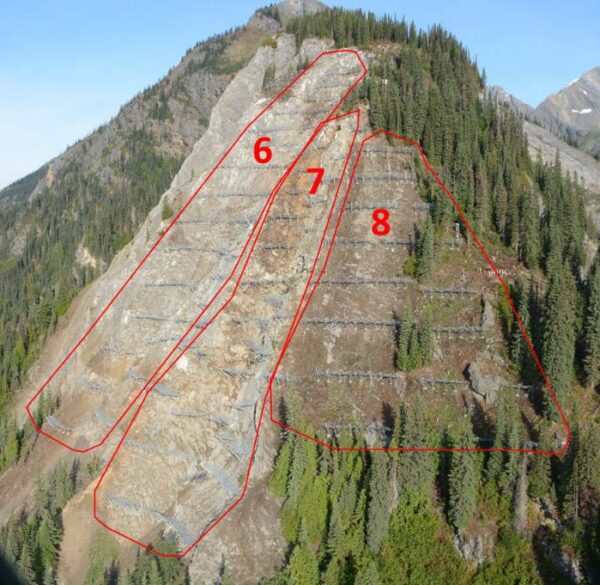

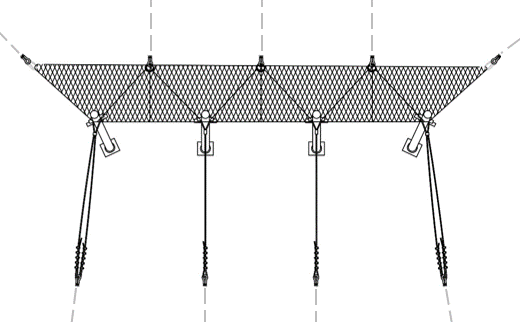

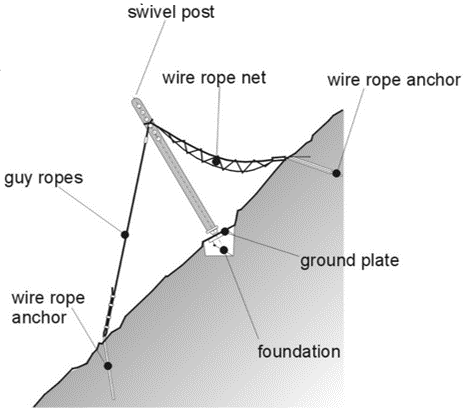

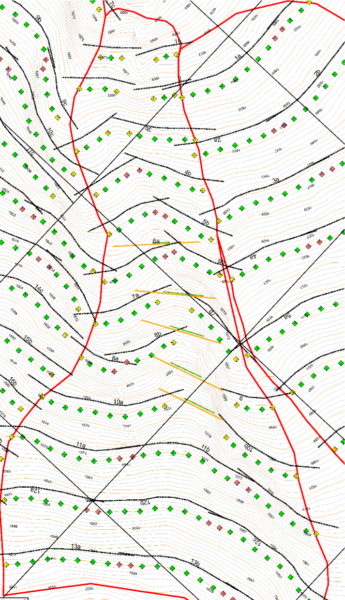

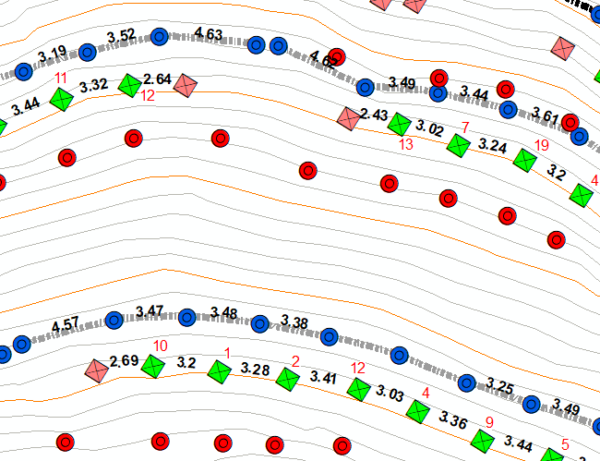

When the Trans-Canada highway was built through Rogers Pass in the early 1960s, several structures and systems were put in place to protect the highway and railway through approximately 150 avalanche paths. These include snow sheds, diversion berms, retarding mounds, a forecasting program, and an artillery control program. For over half a century, these structures and systems have successfully managed winter avalanche risk to trains and vehicles that travel this corridor. More recently, increased traffic volumes and decreased tolerance for road and rail delays has resulted in demand for a new era of avalanche risk mitigation that includes over 14 new remote avalanche control systems (RACS), and the largest installation of snowpack supporting structures in the western hemisphere.

This paper explores both the benefits of snowpack supporting structures and RACS, as well as the challenges in installation for two recent large-scale installations in Rogers Pass. It also discusses numerous other installations that have been completed during this new era, along highway corridors and mining roads.